Interesting build with plans included. I like the “circle” accessory the author added to the build. The author includes plans too if you need them.

https://drive.google.com/file/d/1aDyE6l7CQR3UGKtx-mML0_lG80TtVW8Q/view

Interesting build with plans included. I like the “circle” accessory the author added to the build. The author includes plans too if you need them.

https://drive.google.com/file/d/1aDyE6l7CQR3UGKtx-mML0_lG80TtVW8Q/view

Pretty simple build, basically a wheel with 8 slots in it that you spin the yarn around in.

https://www.instructables.com/Viking-Braids-Make-a-Trollen-Wheel/

The author shows how to make some quick and easy jigs for picture frames. One thing I would do different is add some blocks on the sides to thicken them up.

https://www.instructables.com/Right-Angle-Clamping-Jig-Minutes-to-Make/

The video does a good job explaining why and how you go about doing this. Its an intersting one to watch and helps explain why you would want to do this.

Only downside is each “digit” needs 7 servos, so for 4 digits, that 28 servos. So this could turn into a bit of an expensive build. I think the author should have added in LEDs to the build as well.

https://www.instructables.com/Kinetic-Digital-Clock-Arduino-3D-Print/

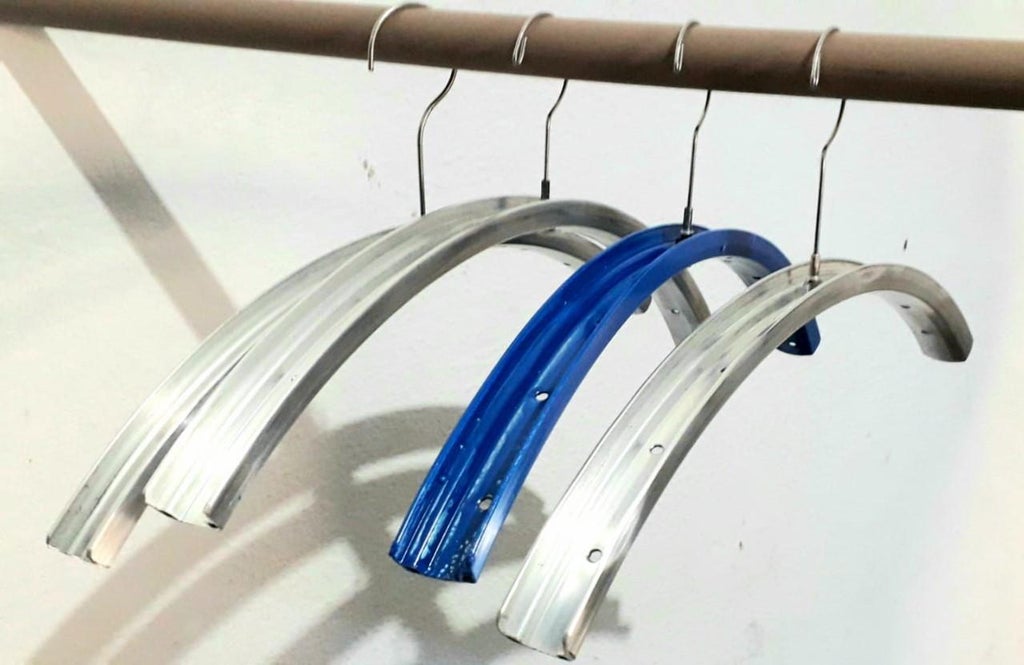

clever project. One thing I would add to it is using an innertube on the rim to prevent clothing from catching onto the metal. It will also help keep the cloths from slipping off.

Nice build for a different sized Hexagon cutting jig. I like how the author makes the backstop, its a bit more complicated than I thought it would be.

Interesting build with old CDROM parts. The author is a little light on how to make one yourself, but thankfully has enough pictures to get the point across.

https://www.instructables.com/Arduino-Powered-Writing-Telegraph/

Interesting build, the author uses a rather big, and clear, touchpad to draw something that the arduino will convert to gcode, which then can be sent to a CNC. This could be a good kid project (they draw something, then it gets printed or cut out). Outside of that I usually just scan in an image and tweak it with inkscape.

If you need some tall, or custom shape toggle clamps, this is the way to go. Me…too much work I will just go to Harbor Freight and buy them.

However, the author does include templates, which could be converted to run on a CNC…which would make these much easier to build….hummm.

https://www.homemadetools.net/forum/new-design-diy-toggle-clamp-86209?homelistings#post184724